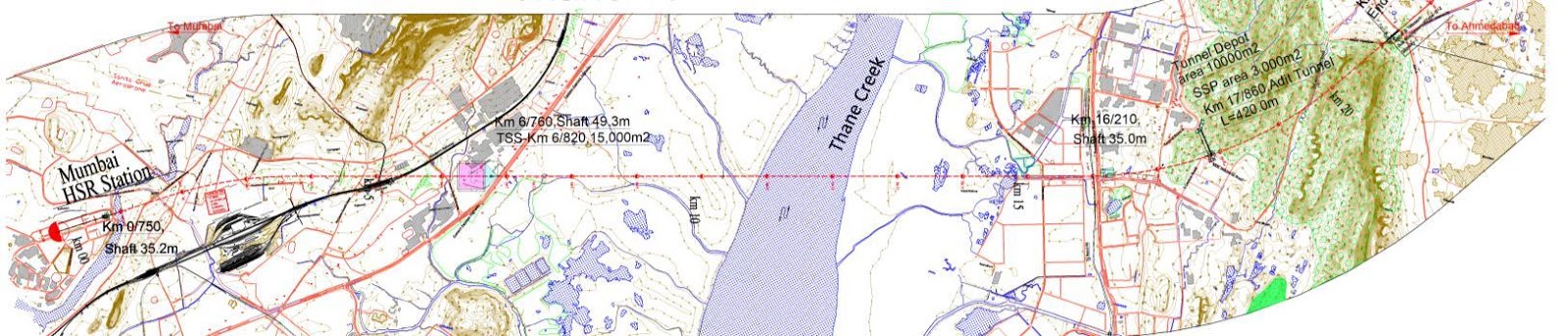

Proposed high speed rail corridor will pass through Thane Creek in Mumbai. Since this area is a protected sanctuary for flamingo and nearby mangroves, rail tracks will be made undersea through a tunnel, thus ensuring no disturbance to existing ecosystem. This tunnel will be longest rail transport and 1st undersea tunnel of India. Tunnel will be a single tube with 13.2 meters diameter to be executed by both NATM and TBM methods in different sections. An underwater static refraction technique was used for the survey work and is now completed.

A schematic route map of undersea tunnel and static refraction survey is as shown here

High Speed Rail Training Institute, Vadodara is being set up alongside National academy of Indian Railways (NAIR), Vadodara. This training institute will be the training ground for all NHSRCL staff. Officers/staff trained in Japan along with Japanese experts will impart training at this institute.

It is aimed that High-Speed Rail Training Institute, Vadodara will serve as a back bone for future development of other High-Speed Corridors in India.

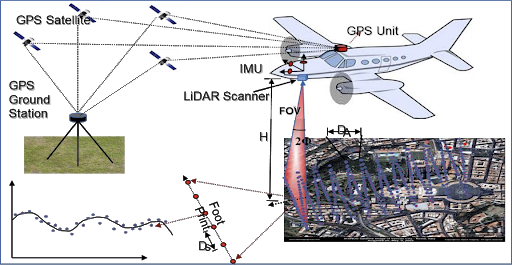

Light detection and ranging (LiDAR) is adopted for the 1st time in a railway project in India primarily because of its high accuracy (100 mm). This technique uses a combination of Laser data, GPS data, flight parameters and actual photos to give accurate survey data. This data is then used for design of alignment of high speed rail corridor, Right of Way

Identification of project affected plots/structures etc.

Approximately 92% of the high-speed railway tack will be elevated through viaducts (as shown in the image) and bridges. Out of 508.09 KMs distance, 460.3 KMs (90.5%) will be viaduct, 9.22 KMs (1.8%) e on bridges, 25.87 KMs tunnels (including 7 KM long undersea tunnel) and 12.9 KMs (2.5%) will be on embankment/Cutting.

There are many benefits of an elevated track. Most importantly, this will ensure no obstruction to natural flow of waters. It provides crossing at all places, sufficient clearance of 5.5 m (i.e. highest for roads) is available over existing road network, greatly improves safety and security perception against external interference and also reduces land requirement (17.5 m width against 36 m for conventional railway tracks).

These trains will be equipped with most advanced signaling system as used in Japanese Shinkansen trains (Japanese Bullet trains). It comprises of primary train detection through coded digital audio frequency track circuits and secondary detection through analog axle counters. Cables used for signaling system will be high quality gas filled ATC cables for higher reliability and safety. This is the first time in Indian railways that we will be using gas filled cables. These cables will be monitored through a cable gas pressure monitoring system. Main benefits of using this system is that these cables help in quick detection of cable crack or breakage and they are moisture resistant.

These trains will be equipped with most advanced telecommunication system as used in Japanese Shinkansen trains (Japanese Bullet trains).

Telecommunication system will use optical fiber cables, which are considered back bone of high speed networking of stations and operational control center. System will be equipped with centrally controlled passenger information system for stations as well as onboard. Same as signaling system, telecommunication system will also use high quality gas filled LCX cables for higher quality and safety.

Same as airplanes, high speed rail will face problems of aerodynamic drag at operating speed and hence designed to reduce drag. Many other fixtures like fairings fitted all around the gaps between cars, side and bottom covers for bogies and other underframe mounted equipment are all fitted to serve the purpose of reducing overall drag.

Moreover, when high speed tunnel exits a tunnel, a blasting sound is generated due to micro pressure waves. Front nose section is the solution to this problem. These are the main reasons for nose shaped aerodynamically designed high speed trains.