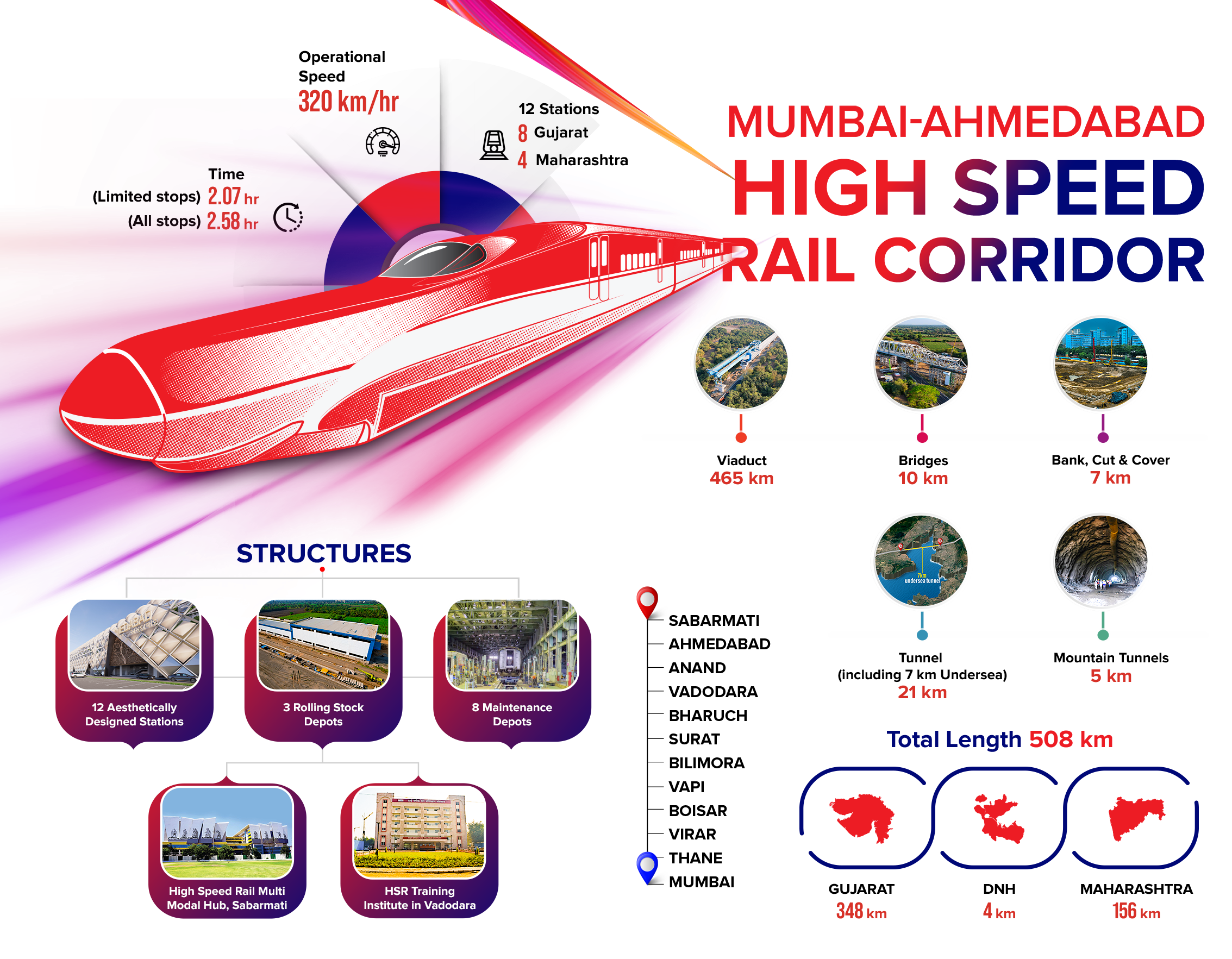

India’s First Bullet Train Project - the Mumbai - Ahmedabad High Speed Rail corridor, spanning across 508 kilometres, will offer fast connectivity between Maharashtra and Gujarat states in western India.

After starting from Bandra Kurla Complex (BKC) area in Maharashtra, the high-speed train running at a speed of 320 km/h will revolutionise intercity travel in the region and will integrate the economies of Mumbai, Vapi, Surat, Anand, Vadodara & Ahmedabad. It will have stops at 10 cities in between namely Thane, Virar, Boisar, Vapi, Bilimora, Surat, Bharuch, Vadodara, Anand, Ahmedabad and will terminate at Sabarmati.

The entire journey will be completed in about 2 hours 7 minutes with limited stops (at Surat, Vadodara and Ahmedabad), which is substantially less than the time taken by conventional trains or road journeys.

National High-Speed Rail Corporation Limited (NHSRCL) implementing this project was incorporated on 12th February 2016 under the Companies Act, 2013 with an object to finance, construct, maintain and manage the High Speed Rail Corridor in India. The Company has been modelled as ‘Special Purpose Vehicle’ in the joint sector with equity participation by Central Government through Ministry of Railways and two State Governments viz. Government of Gujarat and Government of Maharashtra.

As per the feasibility report, the estimated cost of the project is INR 1,08,000 crore (USD 17 billion) excluding taxes and being executed with Official Development Assistance (ODA) Loan assistance from Japan International Cooperation Agency (JICA).

In overall capital structure, 81% of the total cost of the project will be funded by the Government of Japan through JICA. The remaining project cost will be funded by Government of India. According to the equity structure of the Special Purpose Vehicle, 50% is held by the Government of India (GoI), through the Ministry of Railways, and 25% each by the Government of Maharashtra and the Government of Gujarat.

The conditions of the loan being given for MAHSR are at concessional terms and conditions. The tenure of the loan is 50 years at 0.1% interest rate and with a moratorium period of 15 years. Thus, the loan repayment will be done in 35 years.

100% land has been acquired for the project. Out of 1390 hectares earmarked for the line, 430 hectares is in Maharashtra and another 960 hectares is in Gujarat and Union Territory of Dadra and Nagar Haveli.

About 90% of the alignment is elevated and is being constructed mainly using the Full Span Launching Method (FSLM). This unique construction method, is being used for the first time in the country. India is one of the few countries in the world to use and master this technique.

FSLM is 10 times faster than the conventional segmental construction technique used for viaduct construction.

28 steel bridges of spans varying between 60 metres and 130 metres have been planned along the length of the corridor spanning over National and State Highways, Irrigation Canals, River and Railway tracks.

In addition, 24 bridges are being constructed on rivers as part of the alignment, of which 20 bridges are located in the state of Gujarat and 4 bridges in the state of Maharashtra.

The MAHSR corridor will include 8 mountain tunnels, which will be constructed using the New Austrian Tunneling Method (NATM). Seven of these tunnels are located in the Palghar district of Maharashtra, while one is situated in the Valsad district of Gujarat.

Noise barriers are being installed on the either side of the viaduct, to help reduce the noise which will be generated during the operations.

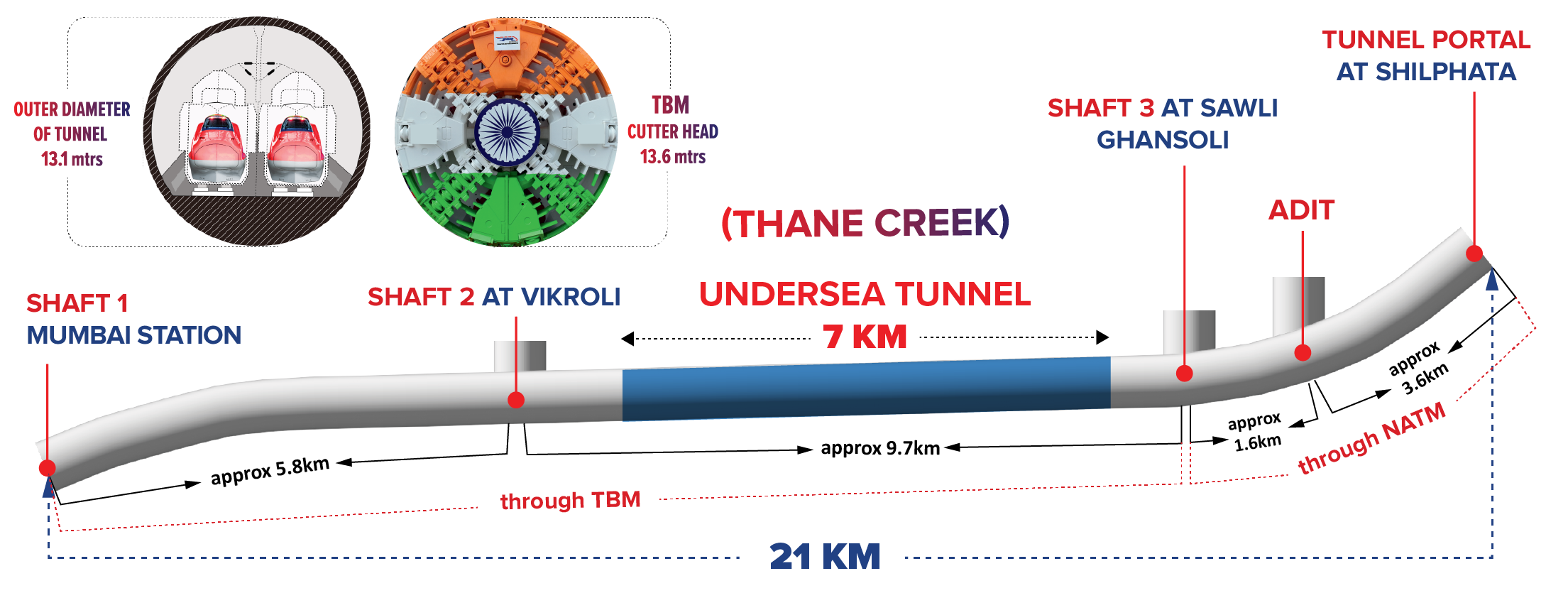

The alignment features a 21 km long tunnel, including India’s first 7 km long undersea tunnel under Thane Creek. The entire 21 km stretch will be constructed using a combination of two tunneling methods – New Austrian Tunneling Method (NATM) to carve out 5 km of the tunnel and the remaining 16 km through Tunnel Boring Machines (TBM).

A single tube of 13.1 m diameter will carry both the tracks in the tunnel. A cutter head of 13.6 m diameter which is the largest for any railways project in India, is being used for the TBMs.

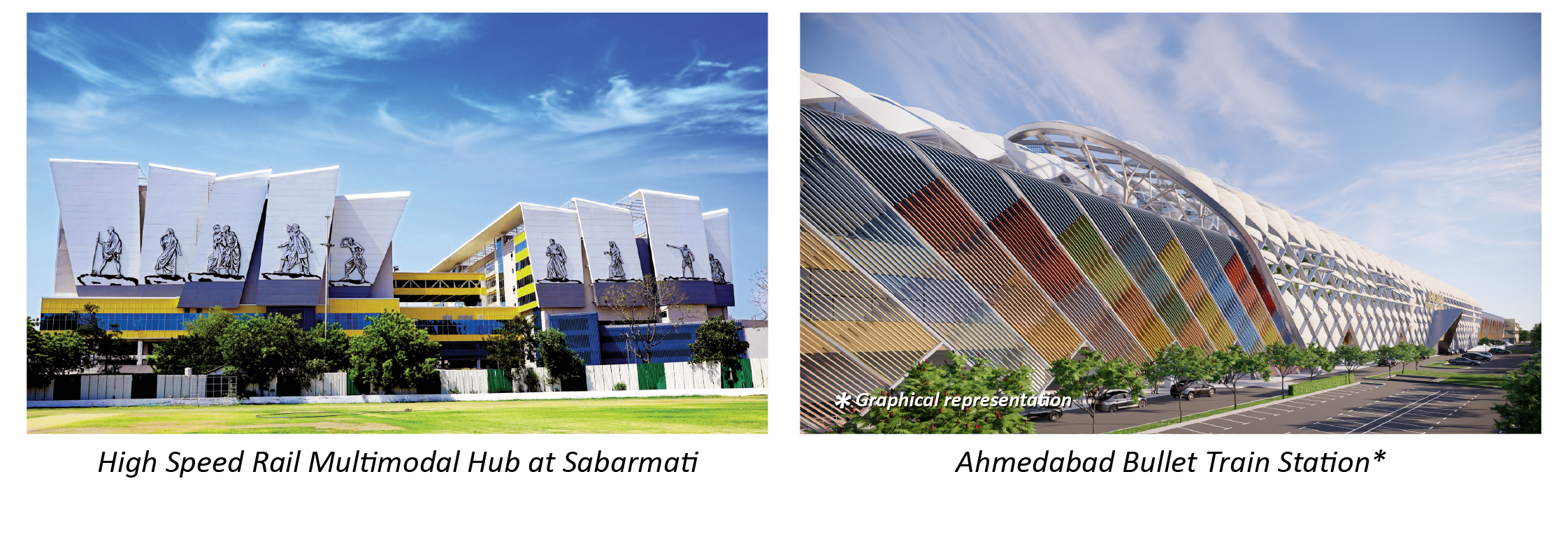

The design of each of the 12 stations on the MAHSR line will reflect the spirit of the city it is located in. This will bring about an instant connection with the local populace, and promote a sense of ownership of the high-speed rail system. The stations are being designed with contemporary architectural facade and state-of-the-art modern finishes.

For a seamless travel experience, the stations on the alignment will be developed as transport hubs through integration with other modes such as metro, buses, taxis and autos for better, faster and hassle-free connectivity to and from the station. Such interface will reduce travel time, enhance accessibility and promote the use of public transportation, thereby decreasing congestion and emissions in our cities.

In order to enhance accessibility & convenience of commuters and to promote economic activities around the station, the surrounding areas are planned to be developed in accordance with the policies of TOD (Transit Oriented Development). The areas around stations at Sabarmati & Surat in Gujarat and Virar & Thane in Maharashtra have also been shortlisted by the respective state authorities for preparation of Station Area Development schemes.

To achieve seamless integration of various transport modes, a multi-modal transit terminal has been constructed connecting Sabarmati Bullet Train station in Gujarat.

The J-Slab track system of ballastless track based on the Japanese Shinkansen track technology is being used for the project. This is for the first time, the J-slab ballastless track system is being used in India.

The entire process of track installation is mechanized with cutting edge machinery especially designed and manufactured as per Japanese specifications. The fleet of machines such as Rail Feeder Car, Track Slab Laying Car, CAM Laying Car and Flash Butt Welding Machine, will be used for track construction work. To understand the methodology of Shinkansen track construction works, extensive training and certification courses are being organised for the Indian engineers, work leaders and technicians on various subjects in the relevant fields by Japanese experts.

The trains for this corridor are state-of-the-art trainsets with consideration of comfort and reliability. The trains are being designed to suit Indian environmental conditions. Three Rolling Stock depots at Sabarmati and Surat in Gujarat and Thane in Maharashtra are under construction.

To meet the energy requirements, 12 traction substations, 2 depot traction substations and 16 distribution substations are being built along the corridor.

Automatic Train Control technology will be used for safe operations of the trains.

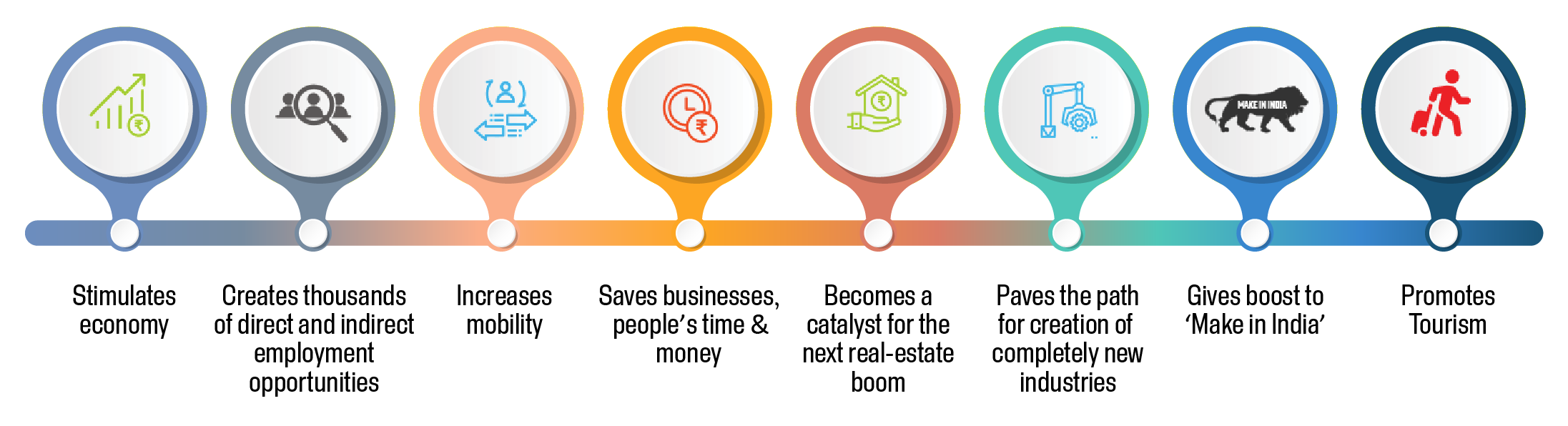

Bullet Train project is stimulating economic growth by creating jobs during construction and operation, while also attracting investment and revitalising areas around stations. By improving mobility and connectivity, Bullet Train will shorten travel time between cities, enhancing worker productivity and fostering business collaboration. It also connects underserved regions to major urban centres like Ahmedabad, Mumbai, Surat & Vadodara, promoting balanced regional development. The project resonates with the PM GatiShakti initiative of transforming India’s infrastructure and connectivity to build a Viksit Bharat, Saksham Bharat & Sashakt Bharat.